What you need to know when implementing weighing tracking system in biscuit factory

What you need to know when implementing weighing tracking system in biscuit factory

Introduction

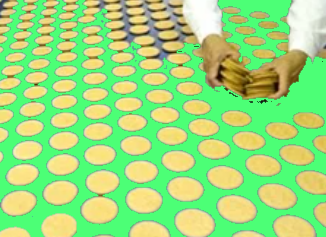

AGen team is implementing a weighing and tracking system in a biscuit factory in Malaysia. We are going through few important points, and we would like to share this point with our customer when they try to implement the similar tracking system in their factory. AGen weigh and trace involves several steps to ensure accurate measurement, quality control, and compliance. Here is a general guide on how to use AGen weighing and tracking system in a biscuit manufacturing process:

weighing system Selection:

Choose a weighing machine that is suitable for the specific needs of your different process in the factory. Consider factors such as production volume, types of ingredients, and regulatory requirements.

Integration with Existing Systems:

Ensure seamless integration with other systems in your factory, such as manufacturing execution systems (MES), enterprise resource planning (ERP), and quality management systems. This integration helps in real-time data exchange and comprehensive process control.

Calibration and Validation:

Calibrate and validate the weighing equipment regularly to ensure accurate measurements. Compliance with industry standards and regulatory requirements is crucial. AGen offer additional tracking capabilities for you to arrange your schedule calibration and maintenance.

Barcode libelling:

Implement barcode labelling for ingredients and finished products. Each batch of ingredients and biscuits should have a unique identifier to facilitate tracking throughout the production process. AGen offer you the barcode printing capability.

User Authentication:

Implement user authentication and access control to ensure that only authorized personnel have access to the weighing and tracking system. Make sure you pre-configure the correct user role and user right when using AGen weighing software.

Weighing Raw Materials:

Weigh raw materials accurately before mixing. The weighing system should automatically record the weight and update the information in the tracking system. You may select to key in or scan in the raw material item code and batch number during the weighing process.

Real-Time Monitoring:

AGen monitor weighing processes in real-time to detect any deviations or errors. Automated alerts can be set up to notify operators or supervisors in case of issues. You can discus with the site engineer to setup the notification during the weighing process or real time data monitoring.

Batch Tracking:

Assign a unique batch number to each production batch. Record and track this batch number throughout the entire manufacturing process, including mixing, baking, and packaging. Batch number will allow you to have a complete track and trace capability in future.

Quality Control Checks:

Integrate quality control checks within the weighing and tracking system. This may include checking the weight of individual biscuits, ensuring uniformity, and meeting specified quality standards. Consistent quality and quality make sure your product quality at the end of the process.

Documentation and Reporting:

Maintain comprehensive documentation of all weighing and tracking activities. Generate reports regularly to analyse production efficiency, identify trends, and ensure compliance with quality standards. Based on the generated report, you can have clear picture of the product in your factory. Always request new report format from AGen engineer to simplify your data mining process.

Traceability:

Establish traceability by recording key information such as ingredient sources, production dates, and batch numbers. This information is crucial for quality assurance and in the event of a recall. The existing of AGen is to simplify you on this process.

Training Operators:

Provide training to operators on how to use the weighing and tracking system effectively. Ensure that they understand the importance of accurate weighing and proper data entry. Every data capturing process bring organisational unpredicted information in future and improve your product quality by the end of the tracking.

Regular Audits:

Conduct regular audits of the weighing and tracking system to verify its accuracy and compliance with regulatory standards. AGen come with regulatory follow up module to allow your maintenance department to follow up closely with machine maintenance and regulatory inspection.

Summaries.

By following these steps, a biscuit factory can effectively use a weighing and tracking system to enhance accuracy, improve quality control, and ensure compliance with industry standards. With the consistent production quality, with consistent sales value, management can spend more effort in new product invention and marketing in order to improve factory revenue.

By:

pang

| Date:

27 Feb2024