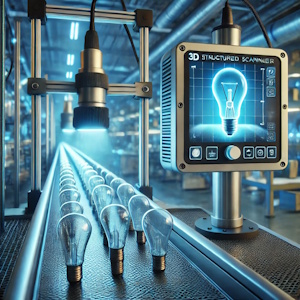

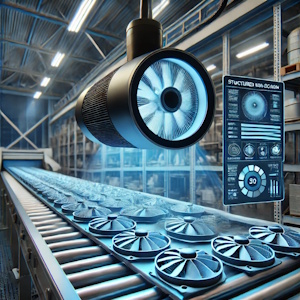

AGen 3D Vision Surface Inspection: Enhance Raw Material Quality & Efficiency

21/Feb/2025

Introduction

AGen 3D vision surface inspection solution uses advanced imaging and AI algorithms to detect defects, contamination, and inconsistencies in raw materials upon arrival. It employs laser triangulation, structured light, or stereoscopic cameras to create high-resolution 3D surface profiles, capturing depth, texture, and shape variations. For food, metals, and industrial materials, it identifies cracks, rust, dents, bruises, or foreign objects like plastic and metal fragments. AI-driven analysis compares scanned materials to reference models, ensuring compliance with quality standards. Integrated with automated sorting systems, it helps reject defective items, improve supplier accountability, and enhance production efficiency. This solution reduces manual inspection errors, prevents defective materials from entering production, and optimizes the warehouse receiving process.

Feature

🔹 High-Resolution 3D Scanning – Uses structured light, laser triangulation, or stereoscopic imaging to capture precise depth, shape, and texture details of raw materials.

🔹 AI-Powered Defect Detection – Identifies cracks, dents, rust, bruises, contamination, and foreign objects with machine learning algorithms.

🔹 Automated Quality Grading – Classifies materials based on size, shape, surface uniformity, and industry quality standards.

🔹 Real-Time Processing & Alerts – Provides instant feedback on material defects, enabling quick decision-making and rejection of faulty goods.

🔹 Multi-Material Inspection – Supports metals, food, wood, textiles, plastics, and more.

🔹 Traceability & Reporting – Logs inspection results for supplier compliance tracking and regulatory audits.

Advantages

✅ Higher Accuracy – Captures depth, shape, and texture variations that traditional 2D cameras and manual inspections may miss.

✅ Faster Inspection Process – Automates quality checks, reducing inspection time from minutes to seconds, increasing warehouse efficiency.

✅ Improved Defect Detection – Identifies cracks, dents, bruises, contamination, and foreign objects with AI-driven precision.

✅ Reduced Manual Errors – Minimizes human subjectivity and fatigue-related mistakes, ensuring consistent quality control.

✅ Enhanced Supplier Accountability – Provides detailed reports and traceability, helping monitor supplier quality and enforce compliance.

✅ Waste Reduction & Cost Savings – Detects defects early, preventing defective materials from entering production and reducing waste and rework costs.

Summaries

AGen 3D vision surface inspection automates raw material quality control using high-resolution scanning and AI-driven defect detection. It ensures accuracy, speed, and traceability, reducing manual errors and waste. By identifying defects early, it enhances supplier accountability, optimizes inventory management, and improves warehouse efficiency, leading to cost savings and better production quality.

More Raw Material Department Solution

https://www.alcaidc.com/public/Solution/RawMaterialWarehouseDepartment/Introduction.aspx

by:

pang

|