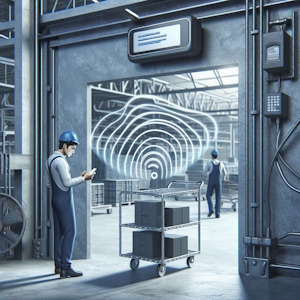

1. Real-Time Trolley Tracking

RFID enables instant visibility of trolley locations throughout the factory. This reduces time spent searching for equipment and ensures that materials are where they need to be, improving workflow efficiency.

2. Improved Inventory Management

With RFID, you can automatically track trolley location. This helps speed up the inventory delivery, reduces manual errors, and supports just-in-time (JIT) manufacturing practices.

3. Enhanced Productivity

By automating tracking, workers spend less time on administrative tasks and more on value-added activities. This leads to faster turnaround times and better resource utilization.

4. Loss and Theft Prevention

RFID systems can alert managers if a trolley leaves a designated area or is missing for too long, helping to prevent loss or unauthorized movement of valuable assets.

5. Data-Driven Decision Making

RFID systems generate detailed logs of trolley movements and usage patterns. This data can be analyzed to optimize routes, reduce bottlenecks, and improve overall operational efficiency.