AGen case packing recording and management solution make your delivery simple.

AGen case packing recording and management solution make your delivery simple.

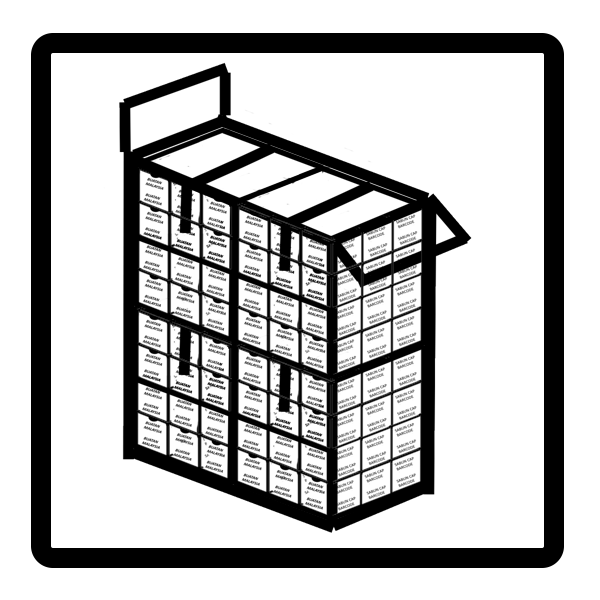

Case packing in manufacturing refers to the process of organizing and placing individual carton box into a bigger cardboard box or container, typically called as master case. This is an essential step in the final stages of packing before a product is arrange onto pallet. Case packing can involve automated machinery or manual labour depending on the scale of production and the type of products being packed.

AGen Case packing recording and printing in manufacturing refers to the process of recording of carton box placing into bigger cases or boxes for palletizing. This process is crucial in industries where products need to be transported in bulk quantities efficiently and securely and the information inside the big carton box need to be display clearly. AGen case packing will product a label sticker with QRCode printed, once user scan the QRCode on the label, he/she will be able to know what the item inside this big carton box is. At the same time, an A4 sheet shipping document will also be being product for reference purposes.

Key aspects of case packing include:

Carton handling and recording: Ensuring carton are handled carefully to prevent damage during packing. The worker will capture the carton box identity and to be linked to the master case

Efficiency: Maximizing the speed and accuracy of packing to meet production demands.

Packing Requirements compliance: Adhering to specific packaging requirements such as weight limits, stacking configurations, and product orientation inside the case. At the same time it also checking packed cases for accuracy, integrity, and conformity to ensure they meet quality standards. Photo taken for proof purposes.

Logistics and Distribution linked: Facilitating smooth transportation and storage of products from the manufacturing facility to distribution centres or directly to retailers. The carton information will be sent directly to related parties before parcel being picked up.

Overall, case packing recording plays a critical role in the supply chain by preparing products for efficient storage, shipping, and ultimately, retail sale.

There are several reasons why case packing is important:

Protection: Cases shield inner carton from damage during transport and storage.

Efficiency: Cases allow for easier handling and palletizing of large quantities of products. Information delivery can be performed almost instantly.

Security: AGen case packing recording can help to minimised to deter theft or tampering with properly information sending and receiving. Check and auditing of pallet allow manufacturers and supply follow the parcel information online to minimize mistake or missing.

By:

pang

| Date:

24 Jun2024