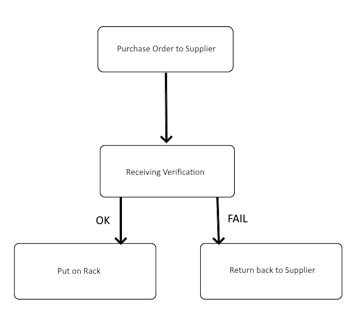

Raw material receiving, recording, and verification is a critical gatekeeping process that ensures incoming goods meet safety, quality, and contractual specifications before entering production. The process begins with verification, where staff physically inspect the shipment for damage, pests, and correct labeling while checking critical parameters like temperature or "use-by" dates. This often includes matching the delivery against a Certificate of Analysis (COA) to ensure chemical or biological standards are met. Simultaneously, recording creates a formal data trail by documenting the supplier name, lot numbers, quantities, and timestamps. By meticulously cross-referencing the physical goods against the purchase order and safety protocols, a facility can maintain full traceability, prevent cross-contamination, and ensure that only high-quality inputs reach the manufacturing line. This dual-action approach is essential for regulatory compliance and protecting the final product from costly recalls.

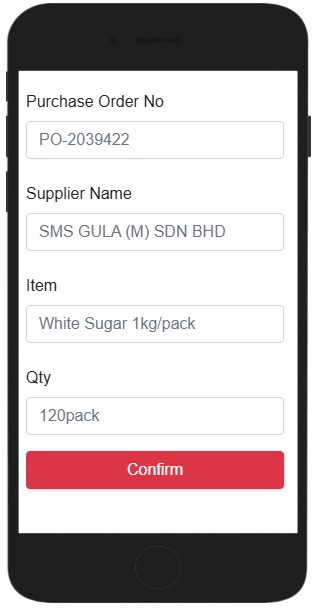

How data is captured:

Barcode / QR code scanning (supplier label or internal label)

Manual entry (if no barcode)

Weighing scale integration (for metal, resin, liquid, etc.)

📌 Best practice:

Generate internal barcode/QR label immediately after receiving.