How to select the barcode scanner for your production floor barcode reading purpose? 7 main features you must consider and 5 optional features may be useful for you. Add on with 3 optional accessories.

How to select the barcode scanner for your production floor barcode reading purpose? 7 main features you must consider and 5 optional features may be useful for you. Add on with 3 optional accessories.

Main feature

1D or 2D barcode scanner

If this is your first time to select a barcode scanner for your factory production requirement, this is the correct article you must read. The first step you need to do is to understand what a barcode is. Once you have understood the barcode, the subsequent question you must answer is, are you planning to use 1D barcode or 2D barcode? Barcode system implemented after 2020 in Malaysia has more than 90% users who will select 2D barcodes due to its compactness and easy to read characteristics. So forget about the conventional 1D barcode symbology which is big in terms of size and long printout. Use QR barcode or Data Matrix instead. This is the easy to scan, low error reading rate and simple to use barcode symbologies for your barcode implementation. First feature you need is a 2D barcode scanner which is able to read 1D plus 2D barcode on your sticker.

USB, RS232 or TCPIP Connection

Once selected the barcode scanner basic capabilities, the next point of scanner selection will be the communication cable required to transfer data to your factory PLC, PC or tablet or mobile device. If your production floor is using PLC as a communication controller with your center server, the RS232 communication cable is the main method of data transfer. This solid, stable and long history communication protocol is the first option for most of the communication methods even until today. However if your factory automation line setup is performed after 2020, TCPIP network connection or USB communication cable may be your main cable selection. Or if you are using many latest tablet devices in your factory production floor, Bluetooth wireless communication method could be the best option. Based on the Malaysia factory setup today, USB cable communication is still the main communication setup used by most of the factory.

Presentation or handheld scanner

Once these 2 major aspects of the scanner are confirmed, the next factor you need to determine is the type of scanning method. You want to scan the barcode by holding the barcode scanner as a gun and read the barcode, or you want to fix your barcode scanner and present the item with the barcode toward the scanner? The main consideration here is the size of the object and location of the barcode on the object. If your production object is more than 200g, it will be easy to pick up the gun sharp scanner and read the barcode, else if your object is small and lightweight, it will be easy for you to present the object in front of the barcode scanning window. If your barcode is sticking on a big object like air conditioner, refrigerator, radio, or car body, it will be ideal to select the wireless barcode scanner to perform the barcode scanning.

Drop test

Above 3 aspects once confirmed, the next consideration is the drop specification of the scanner if you select the scanner which requires the user to hand carry it while scanning, meaning the possibility of scanner drop from the user hand will happen. Higher drop test specifications give better protection by default to the scanner itself. For an entry level scanner, Normally comes with a certified drop test of 1.2meter, the drop test specification increases together with the cost of the scanner. Every increase of 0.1 meter cost a huge price jump on the scanner. The branded scanner required passing the real drop test certificate issued by a third party auditor.

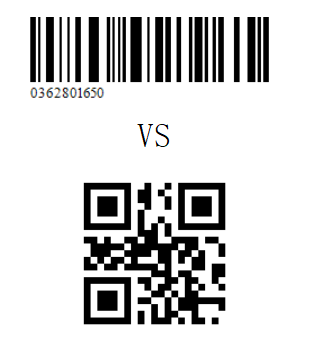

IP rating

Once you select your drop test requirement, the next durability specification is the IP protection rating. In short, higher the rating number means better protection against dust and water splashing on the scanner. Same as drop test, 1 digit increase gives huge difference in terms of pricing of the scanner. For light and medium industry usage, try to get the scanner with IP rating same or above IP52 as your basic requirement. For heavy industry, IP65 or above should be the minimum requirement.

Snappiness of reading

The snappiness of reading for the barcode scanner varies depending on the processor, camera, printed barcode, barcode quality, printing surface, background colour of the barcode, size of the barcode, reading direction, distance between the scanner and barcode and so on. No black and white method to determine the snappiness of scanning, the best way is to try the scanning of the barcode scanner yourself with the comform barcode sample used in your factory.

Minimum resolution the scanner can read

Today a 2D barcode scanner is using camera technology to scan the barcode, from the basics of physics, the camera lens determines the size of the barcode and the distance from the barcode you can read. If you select the scanner to read small or tiny barcodes, the same scanner may have the difficulty to read big size barcodes.

Additional 5 features to make the reading not so boring

Beeper sound

All the barcode scanners come with beeper to indicate to the user he manages to scan the barcode successfully. Some of the scanners allow the user to put in his own beeper sound in order to make the scanning more interesting and to differentiate the scanning station if the operator is standing too close to each other.

Aiming indicator

Different manufacturers give different ways of aiming for the reading barcode. You may find aiming dots, patented boxes, aiming bars from different models of scanner. However the aiming indicator does not affect the scanning performance, it is just a guild for the user.

Good read lighting indicator

1GL, 2GL or 3GL is the common term used in the barcode scanner indicator. GL means green light indicator after successful reading. More green light means better feedback to the user. Always consider the factory operator may need to scan upto few hundred scans everyday. Clear and easy to spot indicators bring better feedback to the user. For sure if you do not want so many indicators, you can disable it anytime from the setting.

The weight of the scanner

If most of the users of the scanner in your factory production line are women, lightweight devices are the preferred device for them. You may compare the scanner weight if the above criteria come to equal when you make the decision.

Environmental Compliance

To pay little effort to our mother earth, always look for the RoHS components used to build the barcode scanner.

Accessories to improve barcode scanning

Retail Stand

Barcode scanner with a retail stand allows the user to have the option to scan the barcode either present the barcode directly to the scanner or grab the scanner and point to the barcode. Always check with the barcode specialist the availability of the stand for the barcode scanner.

Scanner holder

Barcode scanner holders are used to hold the scanner after the scanning. It allows the user to hang or hold the scanner on the table or on the wall.

Scanner Yoyo

These accessories, useful especially for the scanning station, required the user to stand to scan or to free out some space for the user operating table. With the present of yoyo, the changes for your scanner drop on the floor is almost impossible during the operation.

By:

pang

| Date:

17 Nov2021