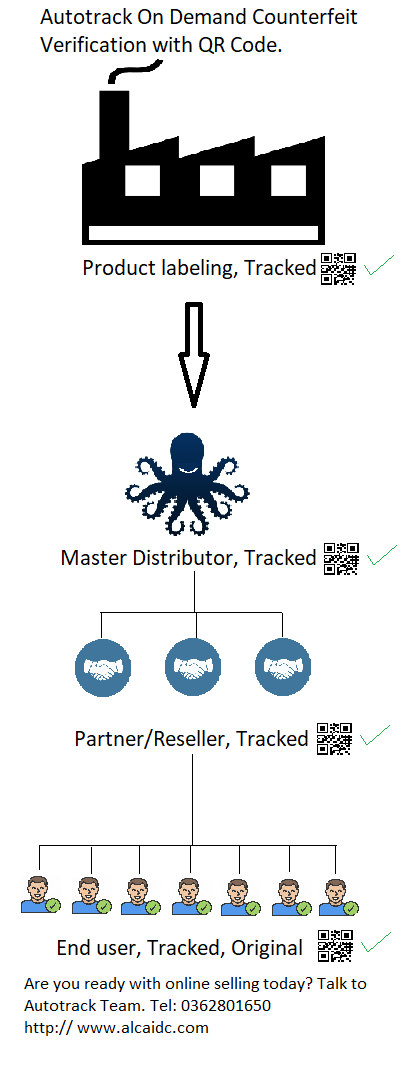

How to track your product distribution starts from your factory until your customer via your distributor, master dealer, reseller and partner by using 2D QR barcode.

How to track your product distribution starts from your factory until your customer via your distributor, master dealer, reseller and partner by using 2D QR barcode.

With the track and trace capabilities offered by the Autotrack team, now our counterfeit verification software enhances you with the distribution tracking capabilities. By using the simple 2D QR code reading capabilities in your mobile device, your distributor, partner, dealer and reseller just need to scan the same printed 2D QRcode printed via Autotrack system during your production stage, then the whole distribution process clearly displays on your computer desktop. On top of counterfeit verification functionality, Autotrack On Demand Counterfeit Verification also offers you the ability to track the distribution by free.

How does the tracking system work?

The tracking start from the last step your product leave your factory production floor**. A well designed 2D QR barcode will be generated by Autotrack solution. You may select to automate this process with an Auto label applicator or laser marked directly on your product. Autotrack team offers you this simple to implement solution. You will select to keep your product into your temporary finished goods warehouse before it is distributed to your master distributor. No additional tasks need to be done on this stage. No man power needs to be added into the existing product distribution activity.

When the product reach master distributor

Product out of factory tracking starts at distributor warehouse, Autotrack On Demand Counterfeit Verification tracking solution offers your distributor multi user login mobile page. With the small investment of today's industry wireless barcode scanner, your distributor can simply feedback the number of products and the unique product flow into their distribution warehouse. The QR code reading is made simple with the wireless 2D barcode scanner.

What to do when the reseller gets the distributed product?

To simplify the tracking on the reseller channel, get an affordable wired 2D barcode scanner from alcaidc to capture the reseller data input page. Connect the wired 2D barcode to Autotrack On Demand Web portal, scan in the resell product 2D QRCode. Now the factory and end user have the full information where the product is passing through and is it an original product source where they purchase the product.

What does the end user need to do after receiving the product?

Product verification scanning with mobile phones is the beginning of customer relationships, Autotrack On Demand counterfeit verification gives your customer a better user experience after purchasing your company product. User experience and education need to be offered to them in order to encourage them to scan the printed 2D QRcode on the product. The end user directly can verify the product original source, the distribution path and the production date of the product. It indirectly increases the brand awareness and quality of the product to the end user.

Product flow and tracking summary

Autotrack Backend server offers a complete information system for the product owner to know where the product flows and where the product is at this moment of time. It gives the overall picture of the product after leaving the factory. This collected big data with a simple and detailed analysis by the marketing department will give the product owner what she/he supports to act as a new step when designing the new product or the accessories for the products.

**Remark, you can even track your factory production flow with our Autotrack On Demand Work In Progress solution.

By:

pang

| Date:

26 Nov2020