What is production warehouse picking and recording process and how to perform this recording?

What is production warehouse picking and recording process and how to perform this recording?

Production warehouse picking and recording process is one of the most critical processes in the production. Proper recording is the key point of quality control at the end of the process. Correct part number being pick and correct batch of material use to prevent any mis-picked of the material during the picking process will give totally different production quality of products.

On this article, let us zoom into the picking and recording process in the factory producing face mask, we take an example of face mask production company who are producing more than 20 type of high end formulated face mask. To produce this different formulated facemask, the production line may require raw material from 8 to 15 different types to be mix and go thru different level of chemical reaction before being apply to the paper mask surface. It is important that the picker of raw material picking the correct batches of chemical base on the chemical shelf life in warehouse as well as the quality tracing after the production. Let see how picking recording can be done.

Step 1

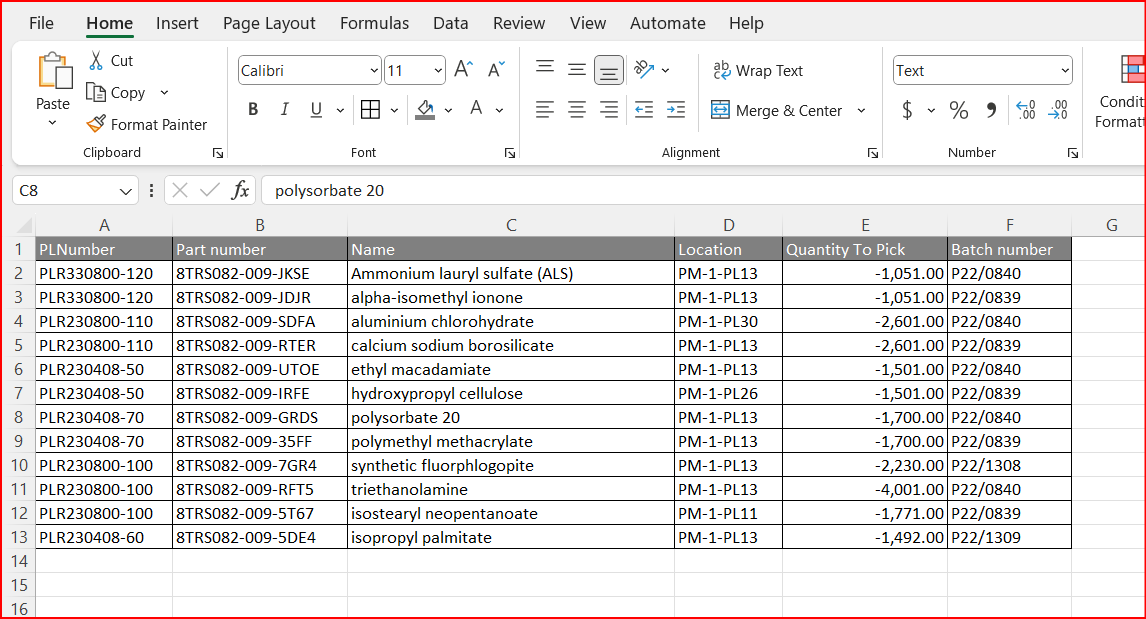

The requester will send in the picking request form to the warehouse department, while this form being imported to AGen software, it will be also printed out for easy picking purposes. The requester will state clearly the raw chemical part number, the raw chemical name and description, the location where the raw chemical located, the batch of the raw chemical to be picked and the required quantity together with unit of measurement of the required raw chemical. Refer to picture 1.0 for sample picking form.

Step 2

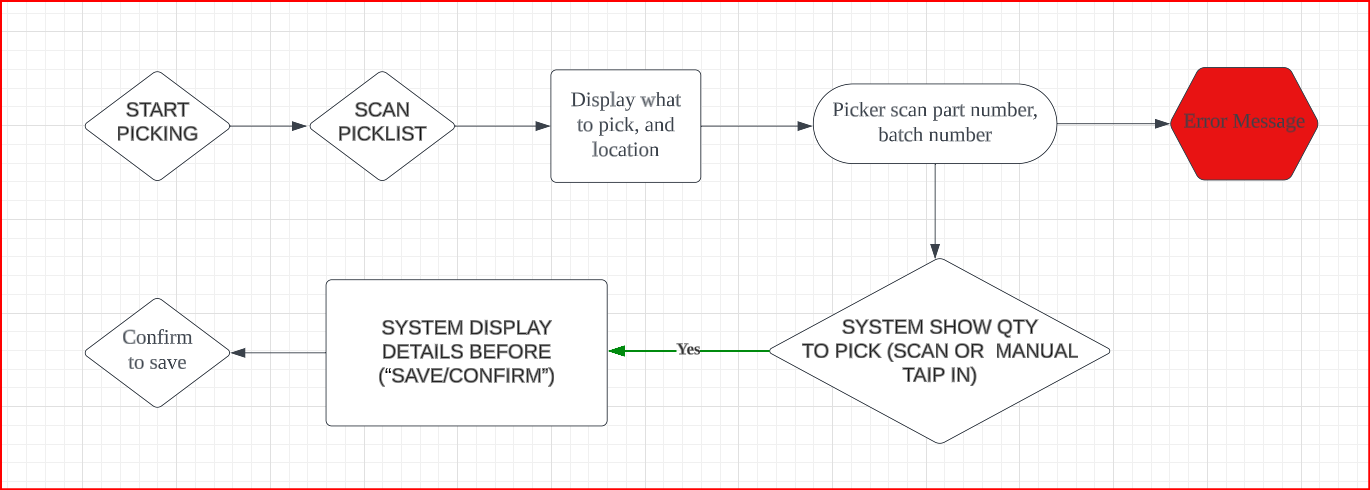

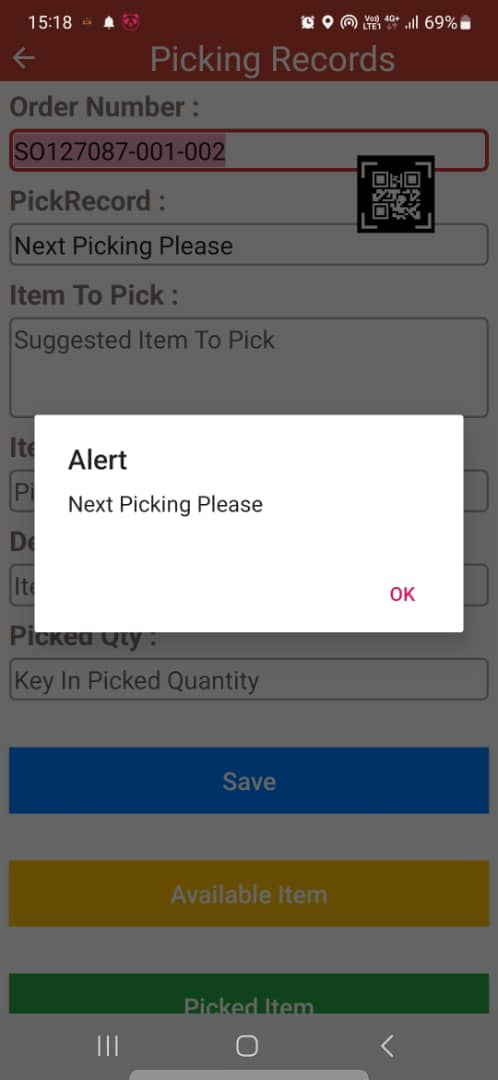

Start the picking recording process by scan in or key in the Picking form number, the AGen software will display the required to pick chemical part number, chemical name or description, location or bin number, batch number and required quantity. After seeing the display, the customer will pick the item, scan the picked item barcode to verify against the picking list and 2nd scan on the batch number to verify the picking request picking batch. Once these 2 verifications are done, the picker now just needs to key in the picked quantity base on the quantity he withdraws from the shelf.

Step 3

Once the pick list finish picked by the picker, the system will prompt the picker to go to next picking list, you can now start the next picking order. You can also anytime to browse the picked item by clicking the picked item button. See the process flow below for the picking process.

Summary

With using AGen production warehouse picking and recording you can easily complete your picking task in your warehouse in shortest time possible. The capture data will be automatically post back to the server and you can anytime export it for your data processing purposes.

By:

pang

| Date:

15 Jun2023