What you need to know about one object one identity in manufacturing production?

What you need to know about one object one identity in manufacturing production?

"One object one identity" is a fundamental principle in the realm of production work-in-progress (WIP) tracking, essential for maintaining clarity, efficiency, and precision throughout the manufacturing process. At its core, this principle dictates that each physical or vitual object undergoing production—whether a component, part, or finished product—must be uniquely identifiable by a distinct identifier. This identifier serves as a digital or physical tag that accompanies the object from inception through completion and beyond, ensuring it can be tracked, monitored, and managed with accuracy.

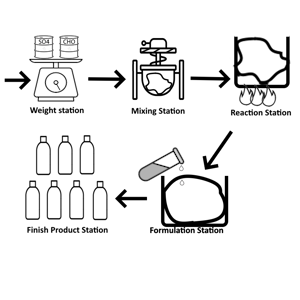

The concept addresses the complexity inherent in modern manufacturing operations, where countless components and products move through various stages of production simultaneously. By assigning a unique identity to each object, typically in the form of a barcode, QR code, or serial number, manufacturers establish a digital thread that links every aspect of an object's lifecycle. From procurement of raw materials to assembly, quality control, packaging, and distribution, the identifier provides real-time visibility into its location, status, and associated data.

With a clear and traceable identity, manufacturers can swiftly pinpoint the source of defects or errors, enabling prompt corrective actions to maintain production timelines and uphold product quality standards.

Moreover, "one object one identity" is integral to regulatory compliance and operational transparency. It ensures adherence to industry standards and regulations that mandate thorough tracking and documentation of production processes. By embracing this principle, manufacturers not only streamline operations but also enhance their ability to make informed decisions, optimize resource allocation, and ultimately deliver superior products to market.

In essence, the adoption of "one object one identity" in production WIP tracking represents a strategic commitment to operational excellence, where clarity, efficiency, and quality converge to drive sustained competitiveness and customer satisfaction in today's dynamic manufacturing landscape.

By:

pang

| Date:

20 Jun2024